Our bonders are manual, with motorized Z & X axis to perform a complete wire bonding sequence with bond termination by clamp tear or table tear.

Our bonders are wedge bonders.

We offer two series of bonders: ES-4029 and ES-4030.

The ES-4029 series utilize ultrasonic or thermosonic bonding method;

The ES-4030 series utilize resistive / parallel gap bonding (welding) method, using split electrode.

In every series of bonders there are some different models:

The ES-4029 and ES-4030 series have the same outer look because the difference is just in the bonding head.

Our standard service includes:

The bonder is operated with a computer mouse. This allows to combine two types of control: by button and by lever (pedal), so two modes of operation: manual and automatic are available at the same time. Manual operation is good for laboratories for bonding prototypes and samples; automatic mode is optimal for high-performance bonding a pre-series or even series of low-loop-count microelectronic devices. You have a lab & fab ready bonder.

The mouse has 8 programmable buttons. This offers a flexible, comfortable and effective operation. A wide range of work modes is available to optimize the work efficiency. For example, a complete bonding sequence of several favourite loop profiles can be programmed to different mouse buttons, so that the user can bond all the loops on a single device without distraction from the microscope.

Loop profile setup is interactive and mouse-aided. The user is just looking at the microscope and moving the mouse to achieve the desired loop length and height. Loop profile setup or tune-up can be done in a few seconds, during a single interactive bonding procedure with a few mouse clicks and movements, without distracting your eyes from the microscope.

The mouse allows both right-handed and left-handed operation: there’s no need for hardware reconfiguration to switch hands.

Changeable bonding head: thin wire, heavy aluminium wire, deep access, even resistance welder — you can get a very cheap all-in-one bonder for all applications.

The bonding head can be replaced in a few minutes. One screw fixation.

All bond settings are digitally programmable. Bond settings and loop profiles are combined to bond presets and can be stored to bonder memory and quickly switched between.

Zero backlash manual cross-roller precision positioning stage offers quick and precise worktable movement:

Our thin wire bonder utilizes high-frequency (110 kHz) and high-Q ultrasonic transducer driven by the built-in self-tuning ultrasonic generator.

A number of researchers found out that high-frequency bonding offers better results in comparison with low-frequency (60 kHz) bonding, allowing to reduce the bonding temperature of gold wire.

For thin wire bonder, in addition to worktable heater, bond-tool heater is also installed. This allows successful gold wire bonding without worktable heating, using bond-tool heater only («upper» heating).

This feature is important for difficult-to-bond applications with limited temperature range.

Precision side wire feed offers great wire & loop control and allows to bond short loops.

The clamping force is digitally programmed to work with different wire diameters.

The wire hole is seen on the left side of the bond wedge (not on the back side), so initial wire insertion into the bond tool can be microscope-aided. This is more comfortable.

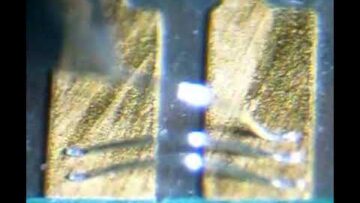

Right-to-left bonding direction offers clear and sharp view of the whole bond loop and all the bond points, when compared with front-to-back direction.

Automatic bond height detection guarantees the loop profile to be constant.

Highest performance in the world within the class of manual bonders: about 10.000 bonds/hour.

In come cases this bonder can be more optimal and cost effective than automatic wire bonder due to its much lower price, simplicity of operation and maintenance-free.

Maintenance-free design with minimal amount of tune-up.

Durability & reliability: no friction, no lubrication, no cooling fans, no heatsinks.

Nothing to do for mechanic and service engineer.

5 years of warranty & decades of failsafe operation.

Large worktables are supported (up to 300х300 mm).

This can be useful for bonding wires on a big-size PCBs.

A low-cost customized set of bond tools for various wire diameters and bond lengths is available ($50/tool, minimum set is one tool).

Specific work modes available:

Trinocular optical video system option is available:

The most compact (400x310x360 mm = 16x12x14 in) and lightweight (16 kg = 35 lbs) bonder in the world.

(If there appeared something even more compact, we’d be glad to hear about it — kindly let us know).

Wire bonding demo

ES-4029 Ultrasonic Manual Motorized Wire Bonder - Manual and Automated work demo

ES-4029 Ultrasonic Manual Motorized Wire Bonder - Manual and Automated work demo